Description

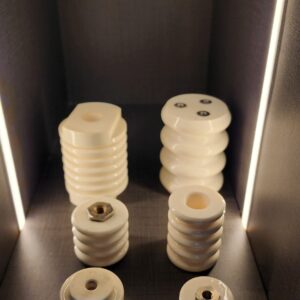

We offer a wide range of hydrocyclones manufactured from our industry proven AL-960 alumina grade chosen for its mechanical strength in high wear applications

Hydrocyclones are used in upstream oil production to separate solids from water or liquid hydrocarbon streams. They prevent the build-up of sand in separators and pipelines, which protects sensitive items such as export pumps and heat exchangers. The liquid-solid mixture is forced through an apparatus at the top of the hydrocyclone and the rotational motion causes dense sand particles to separate from the less dense liquid. The solid particles ‘fall down’ the tube and the liquid is ‘forced up’ the tube into a separate cavity. The hydrocyclones are manufactured in high alumina to be robust enough to withstand severe abrasion caused by the rotational flow of the abrasive sand.

Hydrocyclones are also used in water treatment as part of the in-fracking process offering value in solid / liquid separation from produced water. There is increasing legislation to prevent discharge of solid-contaminated water and a cyclone process can be very effective to remove large solid contaminant from water as a pre-treatment.

We manufacture robust ceramic hydrocyclone liners for efficient sand control and de-sanding separation in harsh environments for the Oil and Gas Industry. The ceramic components are hard wearing and offer a long service life, reliably protecting downstream equipment and enabling users to save costs associated with maintenance and replacement parts.

These liners are manufactured from AL-960 alumina as it has high mechanical strength and has been specially designed for wear applications. AL-960 also offers high thermal stability and excellent corrosion

Reviews

There are no reviews yet.